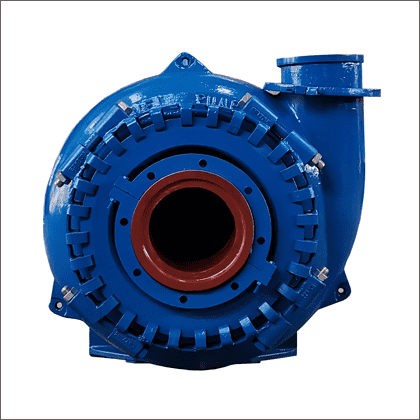

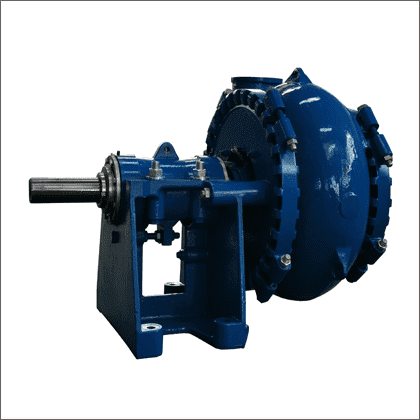

Sand Dredging Pump

Sand Dredging Pump SG series have been designed to increase the pumpability of frothy slurry. The principle of operation is similar to that of hydrocyclone separation.

Vertical Tank Froth Pumps are supplied with parts in wear resistant high chrome iron alloy, with a nominal hardness of 58-65HRC.

The Sand Dredging Pumps are ideal for all applications involving handling of air entrained slurries, such as flotation froth in base metal concentrators, phosphate and apatite washing plants and calcium carbonate upgrading plants. The pump can also be used as a mixing and distribution unit, where dry powder has to be mixed with water.

Material Construction:

| Description | Standard Material | Optional Material |

| Impeller | A05 | |

| Door | A05 | |

| Bowl | A05 | |

| Front Cover | A05 | |

| Back Liner | A05 | |

| Shaft | Carbon Steel K1045 | SUS304, SUS316(L) |

| Shaft Sleeve | 3Cr13 | SUS304, SUS316(L) |

| Shaft Seal | Gland Packing Seal | Expeller Seal, Mechanical Seal |

Application of Sand Dredging Pumps:

Sand and Gravel, Hydraulic Mining, Sugar Beet & Other Root Vegetables, Slag Granulation; Tunnelling.

Specifications:

Pump | S×D | Allowable | Clear Water Performance | Impeller | |||||

Capacity Q | Head | Speed | Max.Eff. | NPSH | No. of | Vane Dia. | |||

m3/h | |||||||||

SG/100D | 6×4 | 60 | 36-250 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 3 | 378 |

SG/150E | 8×6 | 120 | 126-576 | 6-45 | 800-1400 | 60 | 3-4.5 | 391 | |

SG/200F | 10×8 | 260 | 216-936 | 8-52 | 500-1000 | 65 | 3-7.5 | 533 | |

SG/250G | 12×10 | 600 | 360-1440 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 | |

SG/300G | 14×12 | 600 | 432-3168 | 10-64 | 300-700 | 68 | 2-8 | 864 | |

SG/400T | 18×16 | 1200 | 720-3600 | 10-50 | 250-500 | 72 | 3-6 | 1067 | |

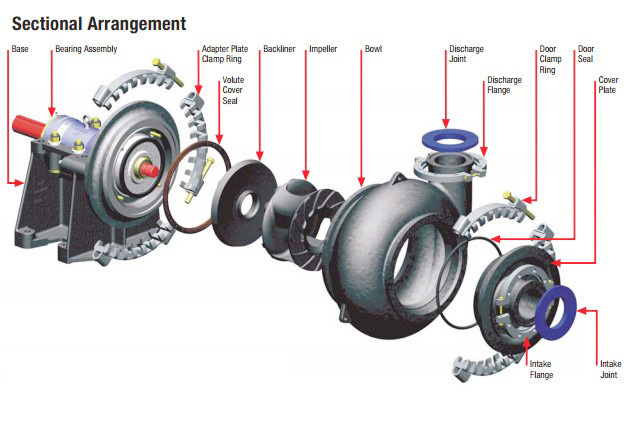

Structure:

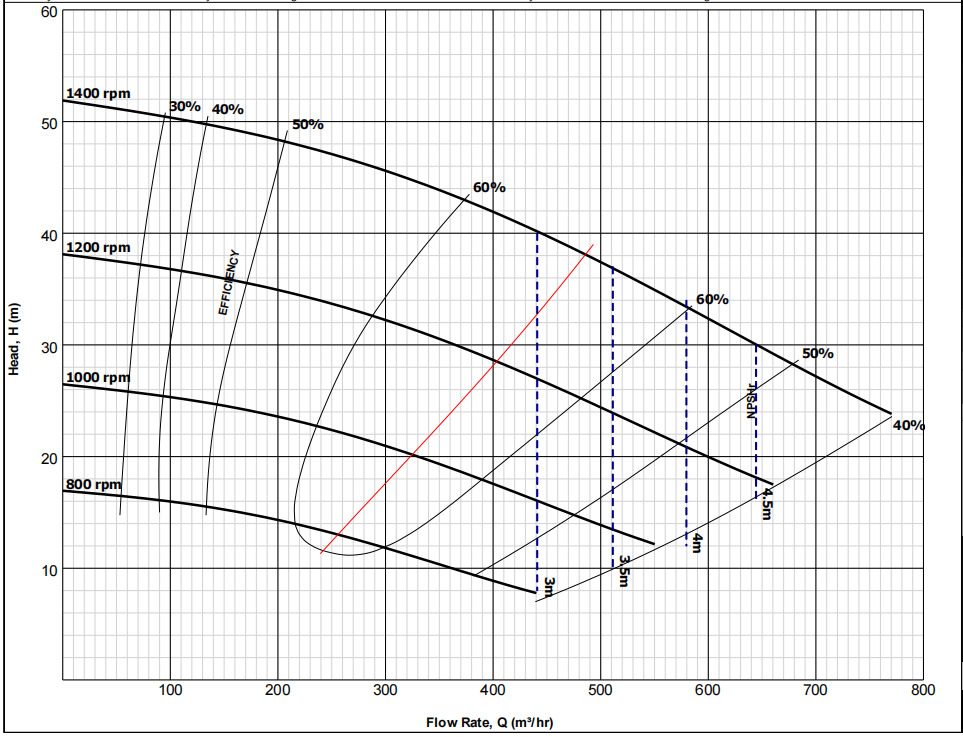

Performance Curve:

Hot Tags: Sand Dredging Pump